How Swell Ratio Testing supports better UHMWPE product design

At Orthoplastics, we have built our reputation on precision, quality and innovation. Our specialist laboratory works extensively with Ultra High Molecular Weight Polyethylene (UHMWPE), Polyetheretherketone (PEEK) and a variety of other high-performance polymers, primarily for the medical device sector.

We are independently accredited to ISO/IEC 17025 by the United Kingdom Accreditation Service (UKAS), giving our customers complete confidence that every test meets the highest international standards. Our goal is simple – to help you ensure your products meet tribological, quality and regulatory requirements so you can bring innovations to market faster and with greater certainty.

The role of swell ratio testing

Swell Ratio Testing is one of the many advanced services we offer. It is an accurate way to determine the crosslink density of UHMWPE – a property that plays a big role in how the material performs. Crosslinking affects wear resistance, mechanical strength and in-vivo lifespan, making it particularly important in applications like orthopaedic implants.

By measuring how much a material swells in a controlled environment, we can calculate crosslink density, molecular weight between crosslinks and the number of repeat units between crosslinks.

Following ASTM F2214, we immerse small, precisely cut samples in o-xylene solvent. The way they swell tells us how tightly the polymer chains are linked. Less swelling means a higher crosslink density, which translates into improved wear resistance and dimensional stability.

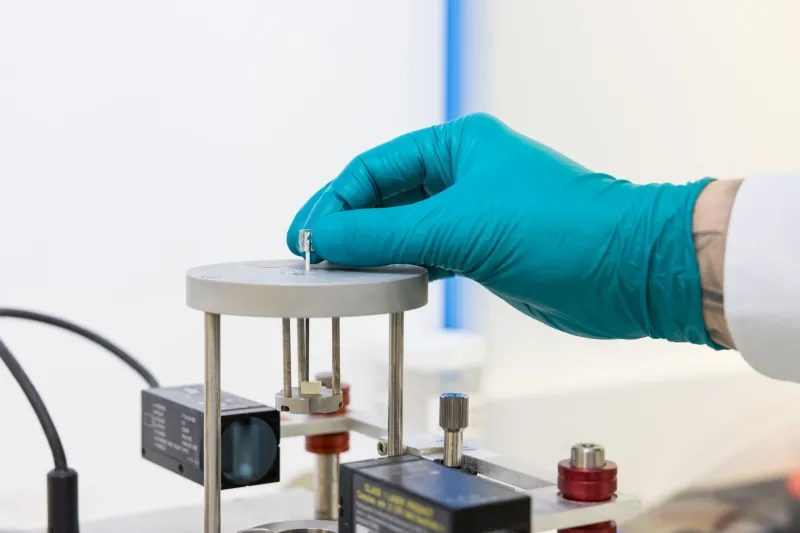

Specialist equipment and process

We use a dedicated Swell Ratio Tester (SRT) for maximum accuracy and repeatability. Each sample measures 4mm x 4mm x 4mm to keep testing consistent. After immersion, we take precise measurements and apply well-established formulae to determine key performance indicators.

It’s a process that combines technical skill with attention to detail – something our lab team takes great pride in.

Helping you design faster

Because we work directly with our customers’ design and development teams, we can build Swell Ratio Testing into the earliest stages of product development. This speeds up the process by confirming material suitability before you commit to tooling or full-scale manufacturing.

We can also create bespoke UHMWPE materials for research and development programmes. This includes evaluating irradiation dose effects, developing custom polymer blends and characterising performance under a range of conditions.

Complete polymer expertise

Swell Ratio Testing is just one part of our wider testing and analysis capabilities. We also offer:

- Failure mode analysis using physical, mechanical and chemical techniques

- Mechanical testing for both short-term and long-term performance

- Chemical analysis to identify polymers and detect contaminants

- Accelerated ageing

- Packaging analysis

Together, these services give you a complete understanding of how your materials will perform in real-world conditions. That means more confident decisions, faster development times and products you can trust to perform.

At Orthoplastics, we’re here to give you the data, expertise and support you need to take your ideas from concept to compliant, high-performing products. Swell Ratio Testing is just one of the many ways we help make that happen.

Get in touch

To learn more about our laboratory services, download our brochure or speak to one of our team today.

Go Back