- LABORATORY

- Research and Development

- Subcontracting

- UHMWPE Quality

- UHMWPE Properties

- Laboratory Brochure

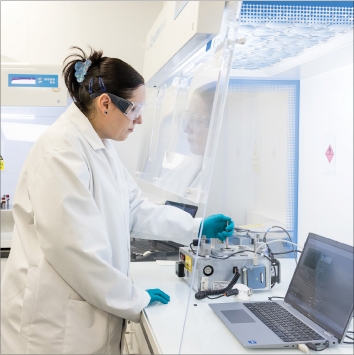

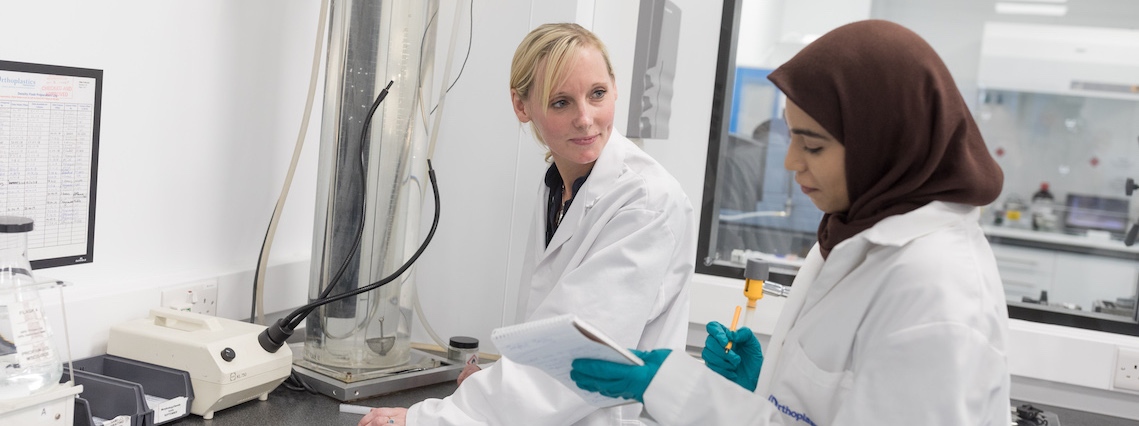

INTRODUCTION

The Orthoplastics laboratory is UKAS accredited and the majority of its projects are carried out in accordance to ISO17025. This industry leading laboratory has been designed and built to support new product development for Orthoplastics’ customers.

It allows customers to accelerate the production process and ensure that all new product concepts meet the application, specification and technical demands required, so that they progress their product to market quicker. It also means that the customer does not have to invest resources to build their own laboratory, thereby avoiding the associated costs and time.